TOPE PRODUCTS

- powder-coat-tapes

- cable-duct-foil-tapes

- electrical-insulation-tapes

- polyimide-film-tape-with-silicone-adhesive

- polyimide-film-tape-with-acrylic-adhesive

- polyester-acrylic-electrical-tape

- polyester-silicone-adhesive-tapes

- nomes- adhesive-tapes

- pet-fiberglass-tapes

- polyester-woven-fiberglass-tapes

- dmd-acrylic-tapes

- electronic-surface-protection-tapes

- bonding-sheets

- polyimide-stiffener

- esd-polyimide-silicone-tapes

- mounting-tape

HBOND SERVICE

- Tape name

- Tape Model

- Tape Specifications

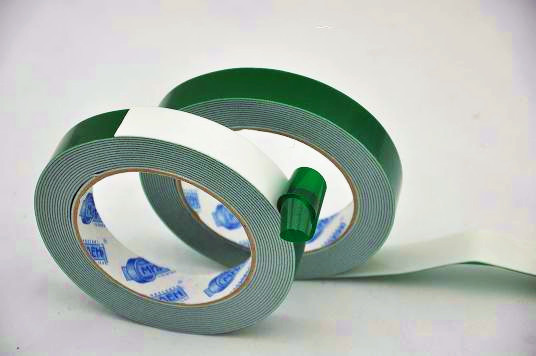

- foam-tape

- ZH-DEA15BP

ZH-DEA15BP is based on ethylene-vinyl acetate copolymer (EVA) foams,

double –sided coated with heat resistance pressure sensitive adhesive,

laminated with release paper.

Product composition:

|

EVA foam base material |

|

Acrylic pressure sensitive adhesive |

|

Release paper/liner |

Physical Parameter

|

Item |

Unit |

Specification |

Test method |

Note |

|

Color |

|

black |

Visual test |

|

|

Backing thickness |

mm |

1.4 |

Thickness gauge |

±0.05mm |

|

Total thickness |

mm |

1.5 |

Thickness gauge |

±0.05mm |

|

Peeling strength |

N/25mm |

12~15 |

GB/T2792-1998 |

|

|

Enduring tack |

H |

≥24 |

GB/T4851-1998 |

|

|

Initial tack |

Steel ball number# |

10# |

PSTC-6 |

|

|

Heat resistance |

℃ |

80 |

|

|

Product Features:

With excellent cohesive force,good holding power、chemical resistance,good sealing and shockproof properties.All items comply with ROHS requirement.

Application ideals:

Widely used as heat preservation, sealing, shockproof materials for refrigerator, air

condition ,automobile, electronic and electrical equipment、medical equipment,

precision machine.

|

Others Foam Tape listing |

||||||

|

Model |

Backing Thickness (mm) |

Tensile strength (N/25mm) |

Peeling strength (N/25mm) |

Heat resistance ℃ |

Enduring tack (H) |

Adhesive |

|

ZH-DEA08WP |

0.8 |

15~25 |

≥10 |

120 |

≥24 |

Acrylic |

|

ZH-DER05BP |

0.5 |

15~25 |

≥18 |

70 |

≥24 |

Hot melt |

|

ZH-DPE10BP |

1.0 |

15~25 |

≥10 |

120 |

≥24 |

Acrylic (PE foam) |

Storage condition and Shelf life:

The product should be stored in the ambient temperature, in the 20~80%RH.

You can obtain the best properties within 12 months after product date.

Notes

All above-mentioned techniques are the average values obtained after our several testing by

acknowledged and reliable testing methods. In order to ensure the correct selection and using

of our products. Please make a through understanding both of the purposes and conditions on

usage in advance ,or notify us to provide you with further explanation and service.

Tape Knowledge

- 2010/4/15What is Blue Tape?

- 2010/4/15What is Masking Tape?

English

English